Our Produts

uPVC Conduit Pipe

What is it?

A conduit pipe is a hollow channel through which electrical wires are passed. Think of it as a tunnel that protects cables while keeping them orderly.

Why it is used:

- Guard’s wires against physical stress or impact

- Keeps cable networks organized

- Protects against insects and rodents

- Enhances system safety and reliability

- Simple to install and maintain

Production method:

Created with the uPVC extrusion process, forming long, hollow tubes that can be cut as required.

FRLS Safety Pipes

What are they?

FRLS stands for Flame Retardant Low Smoke. These pipes are specially designed to minimize fire hazards in electrical setups.

Why they are essential:

- Fire resistance:Harder to ignite

- Reduced smoke:Emits less smoke when exposed to fire

- Controlled spread:Slows down fire movement

- Safety in emergencies:Low smoke density improves visibility for evacuation

Special features:

- Made with fire-retardant additives

- Emits minimal toxic fumes during combustion

- Protects wiring systems during fire incidents

- Meets strict safety regulations

How they are made:

Manufactured through extrusion, with special compounds added to enhance flame resistance and reduce smoke output.

uPVC Electrical Junction Box

What is it?

A uPVC electrical junction box pipe is a protective enclosure for electrical joints. It acts like a safety container that keeps wire connections intact and shields them from dust, moisture, and physical harm.

Why it matters:

- Keeps electrical joints secure and reliable

- Prevents wire damage

- Reduces risk of electrical faults or accidents

- Provides easy access for future maintenance or repair work

How it is produced:

Made using the uPVC extrusion method, where heated plastic material is shaped into the required form through specialized machinery.

uPVC Casing and Capping

What is it?

This is a two-piece system used to run wires along walls. The “casing” is the base channel holding the wires, while the “capping” is the cover that conceals and protects them.

Advantages:

- Quick installation on wall surfaces

- Provides a neat, finished appearance

- Easy access for maintenance or rewiring

- Safeguards wires from external damage

- Affordable option for household and office wiring

How it has made:

Both pieces are manufactured using extrusion technology and cut into strips of suitable lengths.

uPVC Electrical Bends

What are they?

These are curved fittings used to change the direction of conduit pipes. They work

like turns in the pathway of electrical wiring, guiding cables smoothly around corners or obstacles.

Benefits:

- Allow neat wire routing around walls and edges

- Avoid sharp bends that could damage cables

- Keep wiring systems tidy and organized

- Offer flexibility in installation layouts

Manufacturing process:

Produced through molding, where molten uPVC is shaped into accurate curves with the help of precision molds.

Flexible Pipe

What is it?

A flexible pipe is a tube or hose designed to carry fluids or gases while allowing for significant bending and movement without breaking or kinking. Unlike rigid pipes, they can easily change direction and adjust to different shapes or pressures.

Why it matters:

- Accommodates movement and vibration in dynamic systems.

- Simplifies installation in cramped or irregularly shaped spaces.

- Absorbs system expansion and contraction due to temperature changes.

- Reduces stress on connections and components.

How it is produced:

Flexible pipes are made by extruding the inner and outer layers of plastic, then adding braided or spiraled reinforcement (like wire or mesh) in between to give them strength, pressure resistance, and flexibility.

Raw material preparation

-

High-grade PVC resin is used as the base

-

Calcium carbonate is added for strength

-

Stabilizers extend durability

-

Additional agents improve performance

Mixing

-

Materials are blended in a high-speed mixe

-

Mixed in controlled cycles for uniform quality

Temperature setting

-

Heat levels are adjusted in a twin-screw extruder for proper melting

Machine setup

-

Dies, mandrels, and sizers are fitted to define product dimensions

Extrusion

-

Heated material is fed into the extruder and shaped

Forming

-

Pipes are centred, calibrated, and checked for thickness and finish

Cooling & cutting

-

The formed pipes are cooled, marked, and cut to length

Testing

-

Samples from each batch are tested in-house for strength, durability, and safety

Dispatch

-

Only approved batches are released for sale

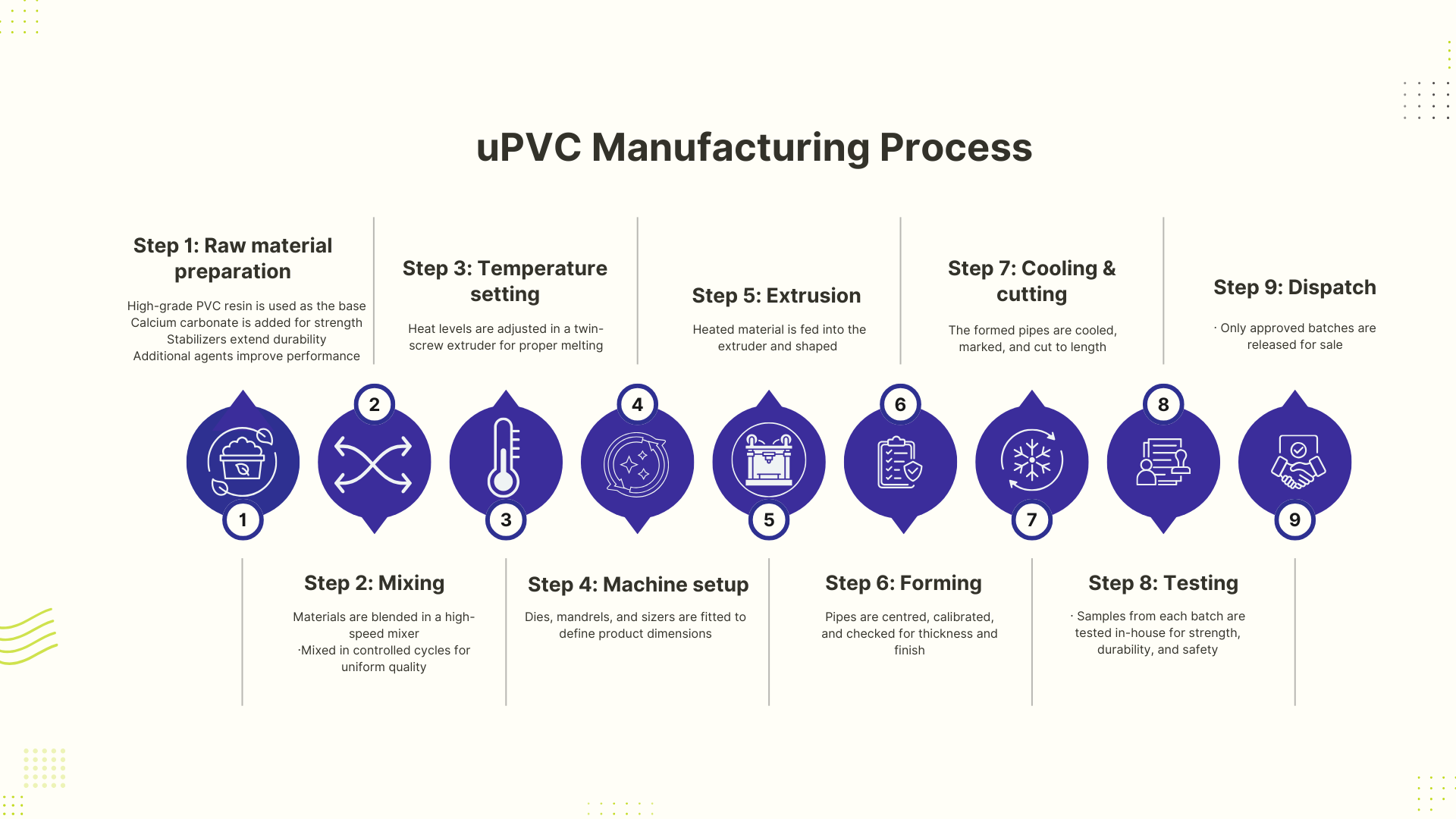

uPVC Manufacturing Process

Step 1: Raw material preparation

- High-grade PVC resin is used as the base

- Calcium carbonate is added for strength

- Stabilizers extend durability

- Additional agents improve performance

Step 2: Mixing

- Materials are blended in a high-speed mixer

- Mixed in controlled cycles for uniform quality

Step 3: Temperature setting

Heat levels are adjusted in a twin-screw extruder for proper melting.

Step 4: Machine setup

Dies, mandrels, and sizers are fitted to define product dimensions.

Step 5: Extrusion

Heated material is fed into the extruder and shaped.

Step 6: Forming

Pipes are centred, calibrated, and checked for thickness and finish.

Step 7: Cooling & cutting

The formed pipes are cooled, marked, and cut to length.

Step 8: Testing

Samples from each batch are tested in-house for strength, durability, and safety.

Step 9: Dispatch

Only approved batches are released for sale.

Molding Process for Accessories

- Used for products like bends and junction boxes

- Heated uPVC is injected into molds shaped for each accessory

- After cooling, the item is removed and finished

- Ensures uniformity and accuracy in every piece

Quality Standards & Certification

All products are manufactured in line with IS-9537: 1983 standards for rigid conduits used in electrical installations. This guarantee:

- Consistent product performance

- Compliance with safety norms

- Long service life

- Reliability for residential, commercial, and industrial use

Note: Always check for certification marks when purchasing electrical fittings. They confirm that the items are tested, genuine, and safe for installation.